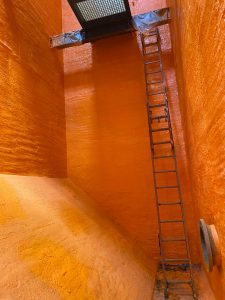

A leading spice manufacturer based in Cockeysville, Maryland had a massively deep lift station structure, about 50 feet deep, that was in need of long-term protection from the corrosive environment of its inherent manufacturing processes. Not only was it very deep, it was also shaped out-of-the-ordinary from the cylindrical or square-shaped structures that are more often seen within general infrastructure.

Due to the logistics of working in a depth like that and for the simple fact that any downtime in a manufacturing plant should be avoided at all costs, ART was selected to apply the OBIC Armor system, which is a multi-layer lining system, consisting of OBIC 1306 (closed-cell foam) sandwiched between two layers of OBIC 1000 (polyurea).

Applied as a seamless coating, OBIC 1000 reduces the likelihood of leaks and weak points in the protective layer, providing a very long service life, and reducing the need for reapplications and maintenance.

The main challenge of the project was the extensive custom scaffolding and platform installation that was needed to effectively and safely spray a structure that deep. Although another subcontractor was in charge of the scaffolding, there were a lot of moving parts to this aspect as they had to utilize the scaffolding and platform for the prepping, priming, and coating of the upper half first and then moving on to the bottom half.

The project was successfully finished in less than two weeks and the customer was able to run at peak operating efficiency with minimal downtime.

ART is an OBIC-certified installer and can offer high-quality, long-lasting solutions for industrial and manufacturing applications. For more information, or to schedule a free, customized product demonstration, call 419-636-2684.