In November 2024, Advanced Rehabilitation Technology (ART) took on a unique and time-sensitive infrastructure challenge – restore and protect a massive outfall structure at the Kalamazoo Water Reclamation Plant, the final destination for about 96 millions gallons a day of treated wastewater before it reenters the river.

This project, part of a larger tertiary treatment system upgrade led by Jones & Henry Engineers, focused on rehabilitating aging infrastructure rather than replacing it. With the plant undergoing major upgrades, the opportunity arose to address the aging outfall structure—which hadn’t been empty in over 40 years. A new structure could cost upwards of millions of dollars, so the decision was made to rehabilitate and start fresh without the hefty price tag and extensive downtime.

An outfall structure is the last stop in the water treatment process, where clean, treated water flows into a nearby natural source, such as a river or stream. In this case, the outfall discharges into the river after going through the tertiary process, the final “polishing” stage of treatment. Aaron Davenport, Senior VP and Kalamazoo Office Director for Jones & Henry Engineers, was featured in a recent episode of Under the Surface, OBIC’s video series, and explained that the water that’s released into the river is often cleaner than the water already in it, as the standards for this level of treatment are incredibly high. In addition, it’s warmer, oxygen-rich, and the fish love it.

Stopping the River and Other Challenges

Working in an empty tank was a rare opportunity, and ART had to maximize every moment, especially given that the State of Michigan required the entire project to be completed within 60 days—a timeline normally reserved for phased work.

Project highlights included:

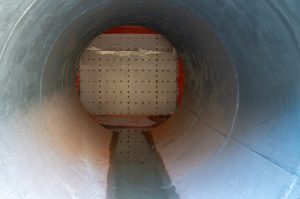

• 8,600 square feet of surface area lined inside the open-top tank using the OBIC Armor multi-layer system

• 96-inch (9-foot) diameter concrete pipe from the tank to the river lined using OBIC 1200

• Headwall repair at the river interface

One of the most significant technical challenges was the pipe below river level. To line it effectively, ART first had to coordinate the installation of a cofferdam to stop the river’s flow and keep the area dry. Another challenge to be overcome by the ART crew was a rain delay due to the tank being open to the exterior.

Preparation included 40,000 PSI water blasting to clean and prepare the concrete surface, scaffolding setup, and coordination with other sandblasting and painting crews. Despite a few weather-related interruptions, ART maintained a flexible on-site crew of 3–6 people, depending on the work in progress.

Expertly Executed When You Need It Most

ART’s longstanding partnership with Jones & Henry was instrumental in the project’s success. The engineering firm knew the performance and reliability of OBIC products. “We’ve worked with ART for years and had great results with OBIC,” said Davenport. “It holds up well, and the speed at which ART can get in and get it done is critical—especially when you’re literally trying to hold back a river.”

The OBIC Armor System not only adds long-term protection against corrosion and wear but also ensures the structure remains easy to clean and maintain. This “reset” will extend the lifespan of the outfall for decades to come, allowing the facility to continue meeting demanding environmental standards without major interruption.

From engineering collaboration to tight project timelines, this 3.5 week outfall rehab project showcased the best of what ART does – delivering efficient, high-performance solutions for critical infrastructure, even under pressure. The end result is a fully restored outfall system, lined, sealed, and ready to serve Kalamazoo County for the next 40+ years.

Interested in learning more about OBIC lining systems or working with ART on your next rehabilitation project? Contact us today to see how we can help protect your infrastructure—above and below the surface.