As you know, the main purpose of a man-sized hole or “manhole”, was to allow workers to enter the sewer system. Manholes have been in existence in the United States for over 200 years, with some still in service dating back to the pre-Civil War era. At that time, bricks and mortar were the common materials used to construct the manholes by hand, but brick was still being utilized well into the 20th century. Fun fact – Specialized brick is still utilized today in unique situations such as industrial applications where the discharge is deleterious to a concrete structure or in a confined, restricted or poorly accessible space where precast sections and the installation equipment required are not reachable.

Other than customized situations, most brick manholes encountered these days are more than 50 years old as precast manholes became the principal manhole structure in the early 1960’s. Clay bricks utilized for manholes are composed principally of silica and alumina, which means they are not affected by the corrosive hydrogen sulfide sewer environment. However, the Portland cement mortar joint is affected by that corrosive sewer environment. After 50 or more years, the mortar joint is severely deteriorated or, most likely, missing altogether.

Many of these original brick sewer manholes are in need of attention and rehabilitation now due to the effects of time. Depending on the location and condition of the manhole, inspections can uncover missing bricks, unstable brick construction, root intrusion and I&I through the missing joints. In some extreme cases, soil can be seen. In the bottom area of the structure, deterioration of the bench or pipe protrusions can sometimes be observed. Structural rehabilitation is necessary in order to restore the integrity of these sanitary sewer manholes. Luckily, OBIC products are flexible enough to be used for the rehabilitation of manholes of all shapes and materials, especially brick. Read more about Ross Township’s experience working with ART to rehab its brick manholes.

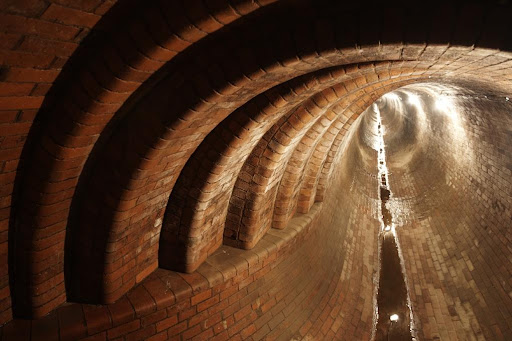

Over the years, OBIC installers like ART have rehabilitated thousands of brick manholes. Some of our favorite stories come from the European installers. They have been faced with rehabilitating ancient structures that are perhaps hundreds of years old. Although the lime-based mortar is long gone on these structures, the meticulous, almost artistic-like fitting and construction work produced manholes that are still functional and structurally sound, like in the image below of an artisan-crafted sewer system. With the OBIC lining system and proper maintenance, these structures can continue to function for another 100 years, which is very impressive.

How do OBIC products work for brick manholes?

When dealing with brick manholes, as a practical matter, any rehab system that affixes to the substrate, requires that the missing mortar joints are refilled, stabilizing the bricks themselves and restoring some structure to the build. For this reason, OBIC Armor spray-applied three-layer system is ideally suited for the rehabilitation of brick manhole structures.

When ART installs the hybrid urethane middle layer of the OBIC Armor system, it expands its size by SIX times forcing its way into the missing mortar joint and restoring integrity to the brick structure. Competitor spray-applied systems do poorly where the wall structure is not smooth and has deep voids or holes, and missing mortar joints could certainly be considered a deep void. In practice, a single-layer sprayed material won’t fill the void entirely, leaving these typical competitive systems to require a trowel-applied filler or backer system to deal with the voids prior to a spray-applied topcoat.

The superior expansion feature of the OBIC Armor system makes it the consummate solution for brick wastewater structure rehabilitation. Want more proof? Learn how ART successfully restored 350 brick manhole structures in Tonawanda, New York!

ART is an OBIC certified installer and can offer high-quality, cost-effective alternatives to the replacement of sewer pipes and manholes. OBIC lining systems are designed to extend the life of the structure by 50 years or longer, and all ART-installed multi-layer systems and OBIC Armor systems include a 10-year manufacturing warranty. For more information, or to schedule a free, customized product demonstration, call 419-636-2684.